The "Tesla Engine" of Space: How Electric Propulsion Sparked a Revolution in Satellite Endurance and Agility

- Oct 25, 2025

- 6 min read

The Gist: Without This Technology, Next-Generation Capabilities Remain Grounded

Picture a traditional satellite's chemical rocket engine: it's like the engine of a Formula 1 car. It delivers a massive burst of instantaneous power, "kicking" a satellite from one orbit to another in minutes. But once its fuel tank is empty, the satellite's ability to maneuver is effectively over. Now, enter Electric Propulsion (EP) systems, particularly Hall Effect Thrusters. These are the "Tesla motors" of space: their thrust is incredibly gentle—often described as "the weight of a piece of paper on your hand"—but they can operate with extreme efficiency, continuously, for days, months, or even years.

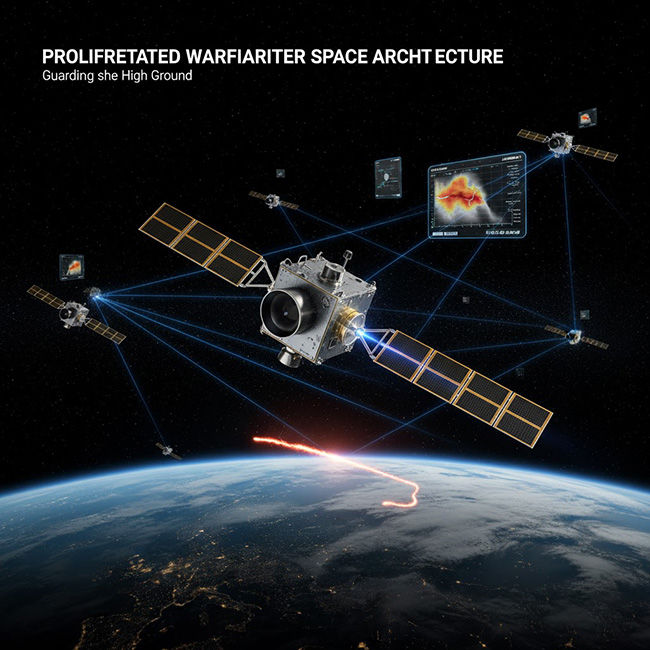

This "slow and steady" accumulation of tiny pushes provides a revolutionary level of endurance. Without this technology, SpaceX's Starlink deployment model—launching a stacked deck of satellites into a temporary orbit and having each one "drive" itself up to its operational altitude hundreds of kilometers higher over several months—would be impossible. This strategy, which radically cuts launch costs, is entirely enabled by EP. Similarly, the U.S. Space Force's concept of "Dynamic Space Operations," which requires satellites that can flexibly change orbits to evade threats or inspect adversary assets, would be unachievable. Electric Propulsion is the key that transforms satellites from passive "cannonballs in orbit" into agile, responsive "space drones."

The Core Tech Explained: Principles and A Paradigm-Shifting Challenge

The Old Bottlenecks: Why Traditional Architectures Can't Counter New Threats

Traditional chemical propulsion works by creating a violent chemical reaction between a fuel and an oxidizer. This produces high-pressure, high-temperature gas that is expelled through a nozzle to generate thrust, a direct application of Newton's Third Law. The advantage is high thrust. The disadvantage is extremely low fuel efficiency.

In astronautics, fuel efficiency is measured by Specific Impulse (Isp), which can be thought of as the "miles per gallon" of a rocket. Chemical rockets typically have an Isp of only 300-450 seconds. This has critical consequences:

Heavy Fuel Load: A significant portion of a satellite's launch mass is dedicated to propellant. This "dead weight" displaces the revenue-generating payload, like communication antennas or imaging sensors.

Limited Maneuverability: Fuel is a finite, precious resource. Every orbital adjustment, collision avoidance maneuver, or station-keeping burn is carefully budgeted. Most satellites can only perform a handful of major orbital maneuvers in their lifetime.

High Launch Costs: A heavier satellite requires a bigger, more expensive rocket. To place a large communications satellite into a geostationary orbit (GEO) 36,000 km high, a 6-ton satellite might be launched, with nearly half of that mass being propellant.

In the era of LEO mega-constellations, which require thousands of satellites to constantly maintain their orbits and responsibly de-orbit at end-of-life, this "brute force" approach is economically and logistically unsustainable.

What Is the Core Principle?

Electric Propulsion operates on a completely different principle. Instead of chemical combustion, it uses electromagnetic fields to accelerate charged particles (ions) to incredible speeds and expel them to create thrust. While the thrust is tiny, the exhaust velocity of the ions can be ten times greater than the exhaust from a chemical rocket. This allows EP systems to achieve an Isp of 1,500-3,000 seconds or more.

The most common type, the Hall Effect Thruster, works in a particularly ingenious way:

Propellant Injection: An inert gas, typically xenon or krypton, is fed into an annular ceramic channel.

Electron Ionization: A cathode outside the thruster emits electrons. These electrons are trapped by a strong radial magnetic field and an axial electric field within the channel, causing them to swirl at high speed and form a virtual "wall of electrons."

Collision and Acceleration: As the neutral xenon atoms drift through this swirling electron cloud, they are struck, and an electron is stripped away, creating a positively charged xenon ion. This new ion is then powerfully accelerated rearward by the strong electric field (a potential difference between the front and back of the channel), exiting at speeds of tens of kilometers per second to produce thrust.

Neutralization: The cathode releases a second stream of electrons to merge with the exiting ion beam, neutralizing it to prevent the satellite from building up a negative charge.

The core purpose of this design is to use a tiny amount of propellant to generate extremely high exhaust velocity, thereby achieving massive specific impulse. This means an all-electric satellite might carry only one-tenth the propellant mass of a comparable chemical-propulsion satellite.

The Breakthroughs of the New Generation

The revolutionary advantages of EP have reshaped satellite design and mission architectures:

Drastic Reduction in Launch Cost: By slashing propellant mass, a satellite's total launch weight can be reduced by 40-50%. This enables launches on smaller rockets or allows many more satellites to be packed onto a single large rocket, directly lowering the primary barrier to entry for space ventures.

Extended Mission Life and Revenue: A satellite's life is often limited not by its electronics but by its fuel. EP allows a satellite to perform station-keeping for 15-20 years, significantly extending its operational and revenue-generating lifetime.

Unprecedented On-Orbit Agility: Satellites are no longer static assets. Dynamic Space Operations become feasible, allowing military satellites to responsively maneuver to fill coverage gaps, dodge debris or threats, and conduct proximity operations for Space Domain Awareness (SDA).

Industry Impact and Applications

The Blueprint to Reality: Challenges from R&D to Operations

Transitioning EP from the lab to large-scale deployment required overcoming significant challenges in power, lifetime, and production.

Challenge 1: The Pursuit of Ultimate Power Efficiency

EP systems are power-hungry. The efficiency of the entire system depends on how well the satellite's raw solar power can be converted into the specific high-voltage, high-current electricity the thruster needs.

Core Components & Technical Requirements: The Power Processing Unit (PPU) is the "brain" and "transmission" of the EP system. To boost efficiency and reduce mass, modern PPUs rely on Gallium Nitride (GaN) wide-bandgap semiconductors. Compared to traditional silicon, GaN components can operate at higher frequencies, temperatures, and voltages with significantly lower energy loss, a critical factor for mitigating mission risks associated with power budgets.

Challenge 2: Achieving Tens of Thousands of Hours of Reliability

The high-energy plasma inside a Hall thruster constantly bombards and erodes the walls of the ceramic channel. This channel erosion is the primary life-limiting factor for the thruster.

Core Tools & Technical Requirements: Extending lifetime is a challenge of materials science and magnetic topology. This involves developing advanced, erosion-resistant ceramic composites (like boron nitride) and, more importantly, designing magnetic fields that shield the channel walls. This magnetic shielding technique effectively levitates the densest part of the plasma away from the walls, extending thruster lifetimes from a few thousand hours to over 50,000 hours, meeting the demands of the most ambitious deep-space and commercial missions.

Challenge 3: From "Artisanal Craft" to "Industrial Production"

With companies like SpaceX and Amazon planning to build thousands of satellites, the demand for EP systems has skyrocketed from a few units per year to hundreds or thousands. Mass-producing these complex devices with consistent performance is a major industrial challenge.

Core Tools & Technical Requirements: This requires a shift to automated manufacturing and testing. Processes from precision machining of components to coil winding and final vacuum chamber hot-fire tests must be automated to ensure quality and consistency. Furthermore, standardized interfaces are crucial for accelerating capability deployment, allowing prime contractors to easily integrate thrusters from multiple vendors onto a common satellite bus, fostering a more resilient supply chain.

Killer Applications: Which Missions Depend on This?

LEO Mega-Constellations: All major players (Starlink, Kuiper, OneWeb) depend entirely on EP for orbit-raising, station-keeping, and de-orbiting.

Geostationary (GEO) Comsats: Modern platforms like the Airbus Eurostar NEO and Thales Spacebus NEO use all-electric propulsion to cut launch mass in half.

Space Domain Awareness (SDA) & On-Orbit Servicing (OOS/M): Agility is the prime requirement. EP provides the high delta-v (change in velocity) needed to rendezvous with, inspect, repair, or relocate other space objects.

Deep Space Exploration: NASA's Psyche asteroid mission and the lunar Gateway space station both use advanced Hall thrusters as their primary propulsion system.

The Future: Challenges to Adoption and the Next Wave

A current challenge is propellant choice. Xenon offers great performance but is rare and expensive. The industry is therefore shifting toward the more abundant and cheaper krypton. There is also intense research into iodine thrusters, as iodine is stored as a solid, which greatly simplifies tank and feed system complexity. The next wave of innovation will focus on much higher-power EP systems (50-100 kW class) and variable specific impulse thrusters that can trade off efficiency for higher thrust, providing the power needed for future crewed missions to Mars and rapid orbital transfers.

Investor's Take: Why the "Picks and Shovels" Play Is Compelling

Electric Propulsion is the lever that is moving the entire New Space economy. It has fundamentally altered the cost equation and capability matrix for satellites. For investors, this represents a classic "picks and shovels" market with a clear and powerful growth thesis.

The companies that manufacture EP systems—including the thrusters, PPUs, and propellant feed systems—such as Safran, L3Harris (Aerojet Rocketdyne), and Northrop Grumman, have built formidable technological moats combining plasma physics, materials science, and power electronics. Their products are now a non-negotiable, mission-critical component for any modern satellite constellation. Investing in these core propulsion technology suppliers is an investment in the entire space industry's inexorable demand for greater efficiency and mobility. As the density of space activity increases, the need for collision avoidance, station-keeping, and active space traffic management will only grow, and it all starts with the faint, steady, electric-blue glow of a Hall thruster's plume.

Comments