Shattering the Iron Triangle: How Digital Engineering Is Forging the Future of Defense Acquisition

- Oct 25, 2025

- 6 min read

The Bottom Line: Without This Technology, Next-Generation Capabilities Are Grounded

Imagine developing a 6th-generation fighter jet. In the traditional approach, teams work in silos on thousands of separate blueprints and documents. Years into the program, the first physical prototype is assembled, only to discover that the avionics racks don't fit, the wiring harnesses conflict with structural members, and the software is incompatible with the flight control hardware. This is the integration nightmare that has plagued defense acquisition for decades, leading to infamous cost overruns and schedule delays.

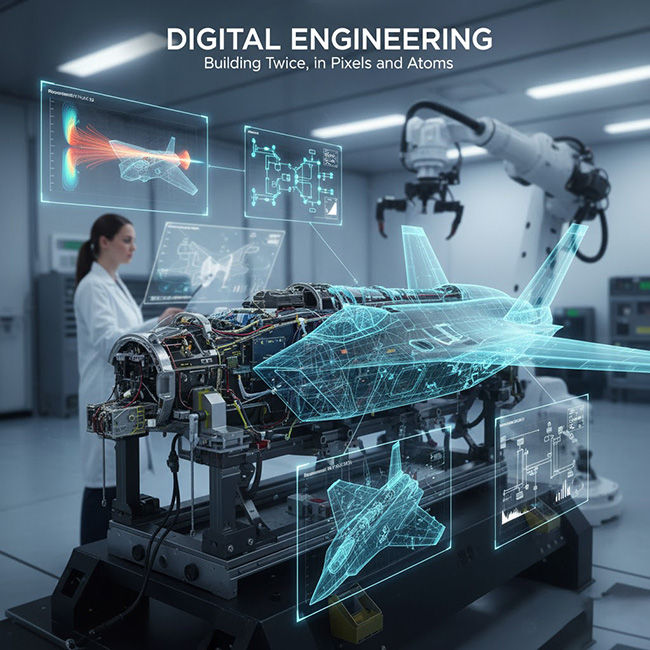

Digital Engineering (DE) is the paradigm shift designed to eliminate this scenario. It replaces the document-centric process with a single, authoritative 3D digital model that serves as the undisputed source of truth for the entire program. When the structures team modifies a bulkhead, the avionics team sees the interference in real-time and reroutes their cabling within the shared digital environment. The software team can "fly" the aircraft in a high-fidelity physics-based simulation long before a single piece of metal is cut. Without this methodology, developing complex "systems-of-systems" like JADC2 or next-generation submarines would inevitably mire programs in a costly, endless cycle of "build-test-fail-fix," fatally compromising the ability to deliver capability at the speed of relevance.

The Core Technology Explained: Principles and Generational Hurdles

Past Bottlenecks: Why Legacy Architectures Failed

The traditional "waterfall" approach to systems engineering, often called Document-Centric Engineering, suffered from three fundamental flaws:

Data Silos: Requirements in Word, designs in CAD files, analyses in Excel, test results in PDFs—program data was fragmented, disconnected, and locked in static formats. Communicating changes was a manual, error-prone process, creating massive inefficiencies.

Reliance on Physical Prototypes: The primary method of design validation was building expensive, full-scale physical prototypes. A late-stage design change could mean scrapping millions of dollars of hardware and months of work.

Late Discovery of Errors: The most catastrophic flaw was that integration issues—especially between hardware and software—were often discovered at the very end of the development cycle. The cost to fix an error at this late stage can be 100 to 1,000 times higher than fixing it during the initial design phase. This chasm between design and integration is known as the "Valley of Death."

This slow, wasteful, and risk-laden process is fundamentally incompatible with the modern need for rapid, iterative capability deployment.

What Is the Core Principle?

The heart of Digital Engineering is the establishment of a Digital Thread, the "digital DNA" of a weapon system. This thread connects every element of the program's lifecycle—from initial concept to final disposal—into a single, continuous digital tapestry.

This ecosystem is supported by three pillars:

The Authoritative Source of Truth: This is the foundation. Using Model-Based Systems Engineering (MBSE), verbose, ambiguous text-based requirements are replaced with a formal, interconnected digital model of the system's architecture, behavior, and requirements. This model becomes the unambiguous reference for all engineering activities, mitigating mission risks associated with misinterpretation.

The Digital Twin: This is the digital representation of the physical asset. In the design phase, it's a digital prototype used for extensive virtual testing (structural stress, thermal, electromagnetic interference). Once the physical weapon system is built and fielded, the model is connected to real-world operational data from sensors, becoming a true Digital Twin that mirrors the health and status of its physical counterpart.

A Collaborative Digital Environment: This is the infrastructure—often a cloud-based Product Lifecycle Management (PLM) platform—that hosts the models and tools. It allows geographically dispersed teams and suppliers to collaborate in real-time on the same authoritative data, breaking down organizational silos and enabling seamless interoperability between partners and allies.

The ultimate objective of this approach is to "Shift Left"—moving the bulk of discovery and validation activities from the expensive physical world to the cost-effective digital realm, much earlier in the development timeline.

Breakthroughs of the New Generation

From Point-in-Time to Continuous Verification: Any change made to the design automatically propagates through the digital thread, triggering updated simulations and analyses. This allows for continuous, automated verification, ensuring the design remains coherent and optimized at all times.

Data-Driven Decision Making: The digital thread provides unprecedented access to data, from early trade studies to real-world performance metrics. This empowers program managers to make critical decisions based on quantitative analysis rather than static PowerPoint presentations.

Accelerated Software Deployment: For software-defined systems like JADC2, the DE ecosystem, when paired with DevSecOps, creates a "software factory." New code can be rapidly tested on a certified digital twin of the operational system and deployed to the field in days or weeks, not years, dramatically accelerating capability deployment.

Industry Impact and Applications

The Implementation Blueprint: Challenges from Lab to Field

Adopting Digital Engineering is a transformative journey that challenges an organization's tools, processes, and culture.

Challenge 1: Establishing the Authoritative Source of Truth

This requires a fundamental cultural shift from a "document" mindset to a "model" mindset.

Core Tools and Technical Requirements:

Model-Based Systems Engineering (MBSE) Tools: Software like Cameo Systems Modeler is used to create the formal system models that serve as the technical baseline.

Product Lifecycle Management (PLM) Platforms: Systems like Siemens Teamcenter or Dassault 3DEXPERIENCE act as the digital backbone, managing the configuration and flow of all program data and enforcing the "digital thread."

Challenge 2: Achieving High-Fidelity, Multi-Physics Simulation

The value of a digital twin is directly proportional to its fidelity. Virtual testing must accurately represent the complex interplay of various physical domains.

Core Tools and Technical Requirements:

Multi-physics Simulation Suites: Tools from vendors like Ansys allow engineers to simulate how a component will react to simultaneous structural, thermal, and electromagnetic stresses.

Hardware-in-the-Loop (HIL) & Software-in-the-Loop (SIL): These techniques connect actual avionics hardware and software to a virtual environment, allowing for realistic testing of integrated systems without the cost and risk of live flight tests.

Challenge 3: Extending the Digital Thread to Manufacturing and Sustainment

To realize the full benefit, the digital thread cannot end at the design review. It must extend onto the factory floor and into the hands of the maintainer.

Core Tools and Technical Requirements:

Digital Manufacturing/Smart Factory: This involves using the 3D model to directly drive automated manufacturing equipment and robotic systems.

Augmented Reality (AR) for Maintenance: A maintainer wearing AR glasses can see a digital overlay of instructions, warnings, and part information on top of the physical hardware, reducing errors and repair times. This is a crucial element for reducing lifecycle costs and improving mission readiness.

Kingmaker of Capabilities: Where is This Technology Indispensable?

Digital Engineering is now the mandated standard for all major advanced U.S. defense programs:

6th-Generation Aircraft (NGAD): The U.S. Air Force pioneered its "Digital Century Series" concept, designing, building, and "flying" multiple virtual prototypes before bending any metal, radically de-risking the program.

Nuclear Submarines (Columbia-class): The first U.S. submarine to be designed entirely in a digital environment, connecting the 3D models directly to the shipyard's manufacturing processes.

Hypersonic Weapons: The extreme physics of hypersonic flight make physical testing incredibly difficult and expensive. Development relies heavily on digital models to simulate aerothermodynamics and material performance.

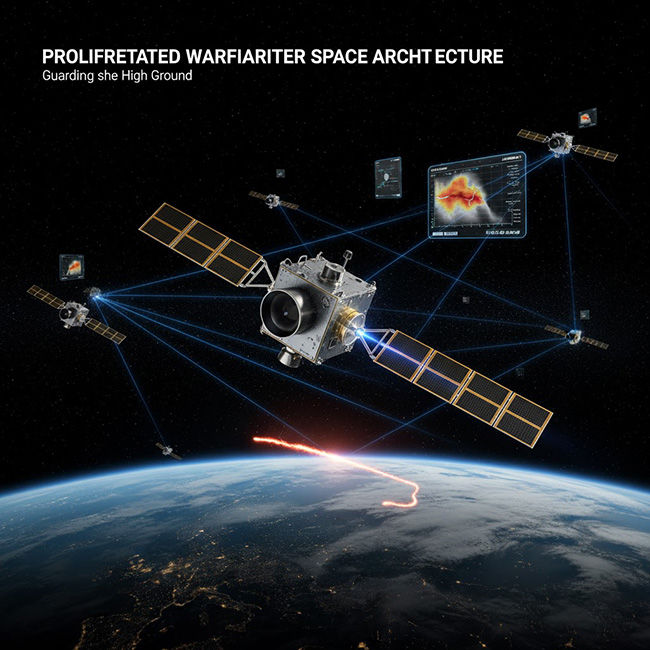

JADC2: As a vast network of interconnected systems, JADC2's architecture can only be designed, tested, and managed within a collaborative digital environment that can model the complex interactions between disparate platforms.

The Road Ahead: Culture, Talent, and the AI Revolution

The greatest barrier to DE adoption is rarely the technology itself, but rather the challenge of transforming organizational culture and reskilling the workforce. The next evolution is already on the horizon: AI-driven Digital Engineering. This includes using Generative Design, where AI algorithms autonomously create and optimize thousands of design options based on a set of performance requirements, presenting engineers with solutions that would have been previously unimaginable.

The Investment Angle: Why Selling Shovels in a Gold Rush Pays Off

The shift to Digital Engineering is a profound, structural change in the A&D industry, creating a durable and growing investment thesis. The primary beneficiaries are not only the prime contractors like Lockheed Martin or Northrop Grumman, but also the software companies that provide the foundational tools and platforms for this digital revolution.

Companies like Siemens and Dassault Systèmes (with their PLM platforms) and Ansys (with its dominance in multi-physics simulation) are the essential "shovel sellers" in this new digital gold rush. Their software is platform-agnostic, deeply embedded across nearly every major defense program, and protected by immense technical and economic moats. Investing in these core "digital enablers" provides a more diversified exposure to the entire defense modernization enterprise, capitalizing on a long-term trend mandated by strategic necessity.

Comments